Dumpmaster

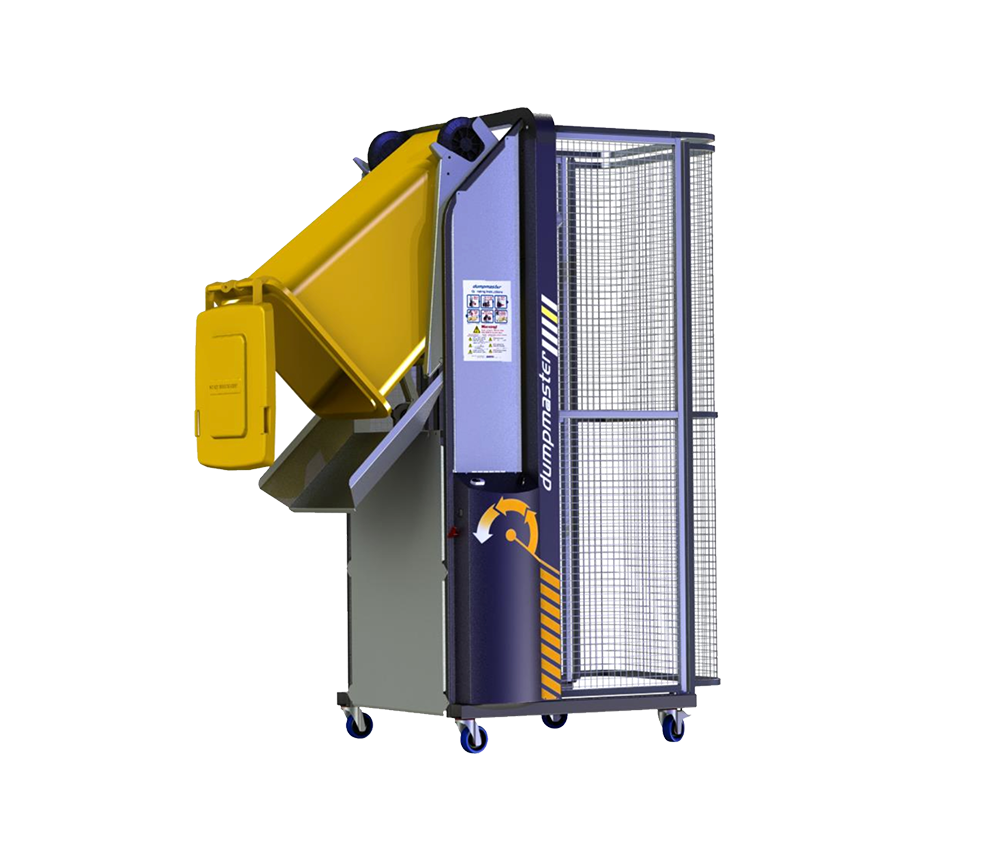

The Simpro Dumpmaster empties any bin at any height, quickly and safely, with an electro-hydraulic mechanism that can lift up to 250kg. The Dumpmaster is the safest and most reliable bin tipper on the market, and has been continuously developed since 1986.

DUMPMASTER SUITABILITY

The Dumpmaster is our recommended bin lifting solution for bins and waste containers of up to 250kg in weight. The Simpro Dumpmaster lifts from 700mm to over 6m in height to help you empty out waste containers into a suitable compactor or baler.

If you are looking for a bin lifter with a heavier weight capacity (600kg) or tipping height (10m), we recommend opting for the Megadumper instead for your bin lifting requirements.

The Dumpmaster is manufactured by Simpro, a New Zealand company specialising in lifting solutions for waste management, warehousing, and food processing. Simpro has developed both the Simpro Dumpmaster and Megadumper, with the inclusion of their own efficient hydraulic tipping mechanism that they are known for in the market today.

You can contact our waste consultants for more information about your requirements or what your current waste management process looks like. We can assist you with evaluating the suitability of a bin lifter for your company and can recommend additional options to ensure your solution is the best fit.

FEATURES

- Huge 250kg lifting capacity

- Tipping heights from 700mm to over 6m

- Weight of bin maintained within machine footprint throughout the tipping cycle

- Powerful, reliable electro-hydraulic mechanism

- Galvanised frame and cradle with zinc-plated guarding, suitable for outdoors use

- Full cage guard with interlocked safety door

- Non-marking castors or optional bolt-down lugs

- Tiny footprint – less than 1m2

- Weathertight control panel with key switch and battery indicator

- Braked castor wheels

BENEFITS

VERSATILE APPLICATIONS

The basic Dumpmaster design is very versatile and is today used in dozens of applications; from emptying rubbish bins into skips to pouring food ingredients into mixers. The electric wheelie bin lifter features a unique geometric tipping action that lifts the bin straight up, then gently rolls it upside down over the lip of the destination receptacle.

SPACE EFFICIENT

Less than 1m3 of floor space is required regardless of tipping height, since the weight of the bin is maintained within the floor footprint at all times.

CREATED FOR SAFETY

The Dumpmaster was designed for safety, with full guarding and door interlock systems fitted as standard. The machine is also certified to comply with various international quality and safety standards, including ISO 12100, AS/NZS 4024, and CE.

No matter how it is used, the Simpro Dumpmaster has proven to be safe, reliable and economical to operate, year after year.

VIRTUALLY MAINTENANCE FREE

Made to last, your Dumpmaster can be used and stored indoors without any worry. This is due to its galvanized mainframe and cradle, zinc-plated cage guarding, and weatherproof controls.

IMPRESSIVE ADD ONS

The Simpro Dumpmaster offers a wide range of useful options to customise your bin lifter. Read more about them below.

- Uprated specifications to comply with machinery safety standards such as ISO13849 and AS/NZS4024, up to Cat4/PLe level

- Full or partial stainless steel construction, for hygiene-critical applications

- Power supply: battery, 1-phase mains, 3-phase mains, or compressed air

- Solar panel for off-grid operation

- Custom cradles to suit virtually any type of container, cart, bin, box or drum

- Dockmaster variant, for emptying bins from elevated loading docks and platforms.

- Custom safety door: left-hinge, right-hinge, swing-up or roller door

- Autocycle controller with adjustable timing

- Digital scales for weighing bins (not trade certified)

- Custom control locations, such as door-mounted, pendant, or remote controls

- Emergency Stop button(s)

- Sheet metal guarding

- PET-G guarding

- Operator Guard (splash shield)

- Foot Guard

- Ironman Kit: heavy-duty bolt-on accessory for equipment hire, construction and military applications

- Bin Hook Kit

- Tipping chutes

Why Choose Dumpmaster?

Innovative Hydraulic Action: Dumpmaster utilises a unique hydraulic action that lifts bins vertically and gently inverts them over the destination receptacle. This advanced mechanism ensures the centre of gravity remains safely within the machine’s footprint, providing stability throughout the tipping cycle. Experience a seamless dumping process in less than 30 seconds!

Versatility and Compatibility: Dumpmaster is engineered to accommodate various bin types, including EN840 wheelie bins, DIN9797 Eurobins, and ANSI trash carts. With standard cradles and the option for custom cradles, it is a versatile solution that adapts to your specific needs.

Multiple Power Options: We understand that different environments require different power sources. That’s why Dumpmaster offers flexible power options, including battery, 3-phase mains, 1-phase mains, solar, and compressed air. Choose the power pack that suits your setup and maximise efficiency.

Safety Focussed Design: Dumpmaster is designed with safety as a top priority. With full-cage guarding, an interlocked door, and CAT1 architecture for PLc safety performance (upgradeable to CAT3/CAT4), you can have peace of mind knowing your operators are protected.

DUMPMASTER SUPPORT & CARE

ONBOARDING

Our team always provide you and your team with operational training for your waste equipment machinery when we deliver your product, in addition to your user manual.

The Dumpmaster is easy to use, with its intuitive interface. However, we’re still always here for you on 1300 435 374 if any questions come up.

TEST & TAG

As a part of your electrical machinery, our technicians provide test & tag services to ensure that your Dumpmaster remains compliant, along with your waste management suite.

Find out more about our full range of support and care services for your waste management.

Need something special?

If you have cause for concern about a high volume of specified waste your company produces, please contact us. Our waste management experts can create a specialised order for handling equipment tailored to the special requirements your facilities require.

Contact Us

Leave us a message and a team member will be in touch